Industrial Heating

When you consider the different ways that we, as a species have evolved, there are several differentiating factors at play throughout the ages. That being said, when you consider the likes of copper, bronze, and iron and how much we have increased and decreased our reliance on them throughout the centuries, there is one common denominator that continues to link them all: heat.

Thousands of years ago, someone realised that heat could be used for a lot more than just cooking dinner. They found that it could transform raw materials and assist in the process of moulding materials and manufacturing different products. The discovery of the likes of glass and ceramics was also the result of high heat and they have massively impacted the way that we live our lives.

Table of Contents

What Is Industrial Heating?

Industrial heating is applying heat to something to improve the way it works and its overall functionality. About 74% of the world’s energy is consumed throughout different industrial processes, and a large amount of this energy usually comes in the form of heat. The amount of heat necessary tends to depend on the actual process, this will also determine what kind of tools are going to be used. It is incredibly important that manufacturing businesses that rely on heat need to research the kind of tools that they are interested in using. By looking at the heat guns from hotairtools.com, it’s easy for businesses to see what kind of temperature they are going to be able to work with and whether this adequately meets their needs.

Common Temperatures for Industrial Heating

When manufacturing businesses are using industrial heating, the temperature that they need is going to largely depend on the process that they are trying to undergo. For instance, a European study found recently that:

- About 30% of all industrial heating processes do not need a large amount of heat, and in fact, they can be done at around 100 degrees.

- Next, 27% of processes are higher and require heatingto 399 degrees.

- Finally, the most common form of heat used in industry is very high, as 43% of processes require heat energy amounting to more than 399 degrees.

We take for granted a large amount that industrial heating gives us. For instance, when glass is used in phones and laptops, heat is required to produce it.

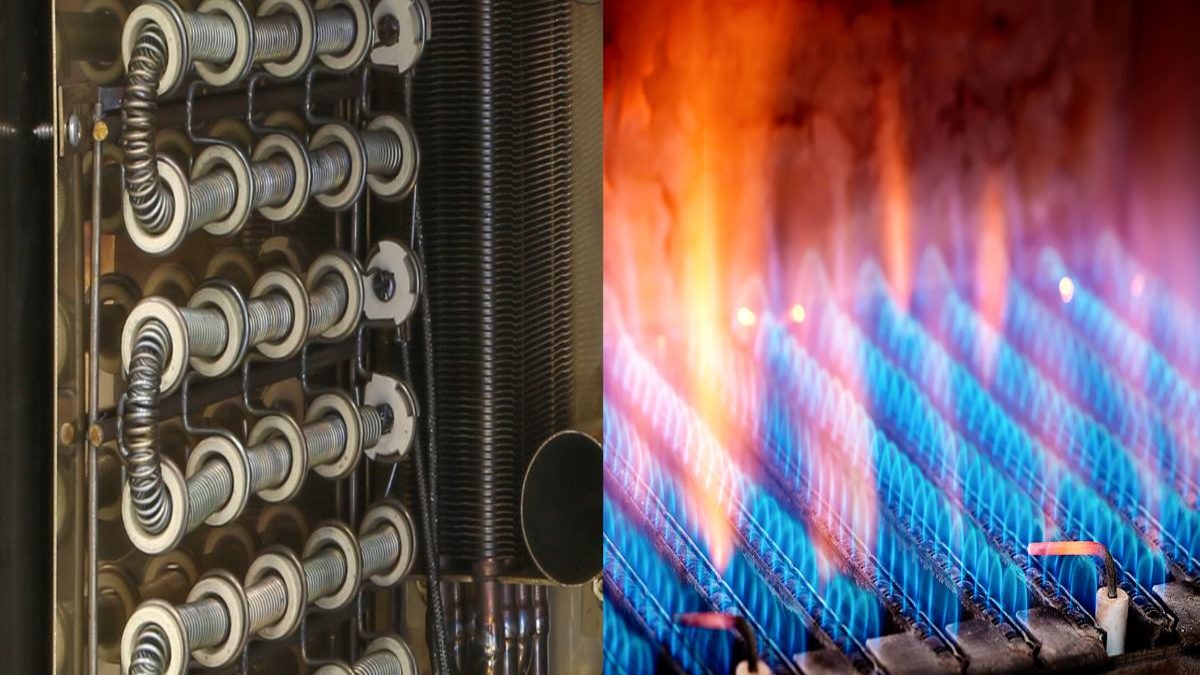

Common Types of Heating in Industry

When it comes to heating in manufacturing businesses, four primary types are used. These include the following:

- Fossil Fuels

- Steam

- Electric

- Hydronic

There are also different hybrid systems present which combine two of these methods.

Conclusion

There is a rich history surrounding heat and how it is used in industry to make things from raw materials. As our use of heat has developed over time, the different ways in which we can effectively apply it to different processes have developed at a similar rate. Some of the most common uses for heat in the manufacturing industry are discussed in detail above.

Review How Different Manufacturing Businesses Use Industrial Heating.